The benefits of an area elevator have been percolating by means of the aerospace group for fairly a while, notably boosted by Arthur C. Clarke’s novel The Fountains of Paradise (1979). The problem is to create the type of materials that might make such a construction doable. Right now, long-time Centauri Desires reader Adam Kiil tackles the query along with his evaluation of a brand new idea in producing graphene, one which might enable us to create the terribly sturdy cables wanted. Adam is a satellite tv for pc picture analyst positioned in Perth, Australia. Whereas he has nursed a long-time curiosity in superior supplies and their purposes, he additionally describes himself as a passionate advocate for area exploration and an newbie astronomer. Right now he invitations readers to think about a brand new period of area journey enabled by applied sciences that actually attain from Earth to the sky.

by Adam Kiil

Within the quiet predawn hours, a spider spins its net, threading collectively a marvel of organic engineering: strands which might be light-weight, elastic, and able to absorbing super vitality earlier than failing. This isn’t simply nature’s artistry; it’s a lesson in hierarchical design, the place proteins self-assemble into beta-pleated sheets and amorphous areas, creating a cloth more durable than Kevlar — in a position to dissipate impacts like a shock absorber — whereas outperforming metal in strength-to-weight ratio, although falling in need of Kevlar’s uncooked tensile energy.

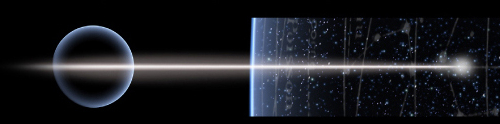

As we gaze upward towards the celebrities, dreaming of bridges to orbit, such bio-inspired ingenuity beckons. May we mimic this to assemble an area elevator tether, a ribbon stretching 100,000 kilometers from Earth’s equator to geostationary orbit and past? The calls for are staggering: a cloth with a particular energy exceeding 50 GPa·cm³/g to help its personal weight in opposition to gravity’s pull, all whereas withstanding radiation, micrometeorites, and immense tensile stresses. [GPa is a reference to gigapascals, the units used to measure tensile strength at high pressures and stresses. Thus GPa·cm³/g represents the ratio of strength to density].

Picture: An area elevator is a revolutionary transportation system designed to attach Earth’s floor to geostationary orbit and past, using a powerful, light-weight cable – doubtlessly made from graphene because of its extraordinary tensile energy and low density—anchored to an equatorial base station and lengthening tens of hundreds of kilometers to a counterweight in area. This megastructure would allow low-cost, environment friendly transport of payloads and folks into orbit, leveraging a climber mechanism that ascends the cable, doubtlessly remodeling area entry by lowering reliance on conventional rocket launches. Credit score: Pat Rawlings/NASA.

Enter a current breakthrough in graphene manufacturing from professor Chris Sorensen at Kansas State College and Vancouver-based HydroGraph Clear Energy, whose detonation synthesis yields pristine, fractal, and reactive graphene — doubtlessly a key ingredient in weaving this cosmic thread.

However this alone might not suffice; we should assume from first ideas, exploring uncharted options to assemble nanoscale wonders into macroscale would possibly.

Graphene’s Promise and Perils: The Historic Context

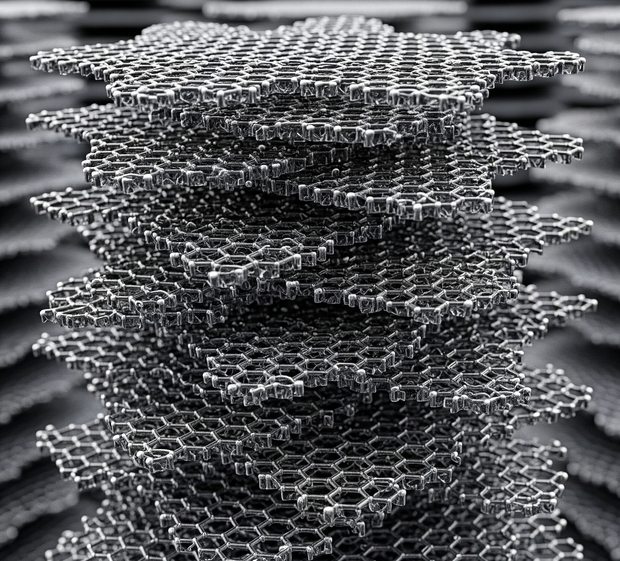

Graphene, that atomic-thin honeycomb of carbon, tantalizes with its theoretical tensile energy of 130 GPa and density of two.2 g/cm³, yielding a particular energy round 59 GPa·cm³/g—proper on the cusp of area elevator viability.

But, manufacturing has lengthy been the bottleneck. Chemical vapor deposition churns out high-quality however restricted sheets; mechanical exfoliation delivers impure, aggregated flakes. These yield composites the place graphene platelets, certain weakly by van der Waals forces (mere 0.1-1 GPa), slip below pressure, like free pages in a e book. For a tether, we’d like seamless load switch, hierarchical reinforcement, and defect minimization—echoing the energy-dissipating nanocrystals in spider silk’s protein matrix.

Sorensen’s Detonation Idea: Fractal and Reactive Graphene

Chris Sorensen’s innovation at HydroGraph Clear Energy flips the script. Utilizing a managed detonation of acetylene and oxygen in a sealed chamber, his group produces graphene with over 99.8% purity, fractal morphology, and tunable reactivity—all at scale, with zero waste and low emissions.

The fractal type — branched, snowflake-like platelets with 200 m²/g floor space — enhances interlocking, outperforming conventional graphene by 10-100 occasions in composites, however crucially, these positive aspects shine at ultra-low loadings (0.001%) and below modest stresses, not but the gigapascal realms of an area elevator.

Reactive variants add edge practical teams like carboxylic acids (COOH), enabling covalent bonding—but, observe that straightforward condensation reactions right here yield strengths akin to polymer chains (1-5 GPa), not the in-plane prowess of graphene’s sp² lattice.This fractal graphene might type a foundational scaffold, reconfigurable into aligned constructions that mimic bone’s porosity or silk’s hierarchy. Earthly spin-offs abound: more durable concrete, delicate sensors, environment friendly batteries. However for the celebrities, we should bridge the hole from nanoplatelets to kilometer-long cables.

Picture: Conceptual view of Hydrographs’ turbostratic, 50nm nanoplatelets, 99.8% pure carbon, sp2 bonded graphene. Credit score: Adam Kiil.

From First Rules: Many Paths to a Cosmic Thread

To transcend these limits, let’s purpose from fundamentals. An area elevator tether should maximize tensile energy whereas minimizing density and defects, distributing stress throughout scales like spider silk’s beta-sheets (crystalline energy) embedded in an extensible amorphous matrix.

Graphene’s energy derives from its delocalized electrons in a defect-free lattice; any meeting should protect this whereas forging inter-platelet bonds rivaling intra-platelet ones. Present strategies fall quick, so listed below are myriad speculative options, drawn from physics, chemistry, and biology—some extant, others nascent or hypothetical, demanding innovation:

- Edge-Fusion by way of Plasma or Laser Annealing: Functionalize edges with hydrogen or halogens, then use plasma arcs or femtosecond lasers to fuse platelets into seamless, prolonged sheets or ribbons, therapeutic defects to strategy single-crystal continuity. This might yield tensile strengths nearing 100 GPa by eliminating weak interfaces.

- Supramolecular Self-Meeting in Liquid Crystals: Disperse fractal graphene in nematic solvents, making use of shear or electrical fields to align platelets into helical fibrils, stabilized by pi-pi stacking and hydrogen bonding. Impressed by silk’s pH-induced meeting, this bottom-up strategy would possibly create defect-tolerant bundles with built-in vitality dissipation.

- Bio-Templating with Engineered Proteins: Design peptides (by way of AI like AlphaFold) that bind graphene edges, mimicking silk spidroins’ repetitive motifs to fold platelets into hierarchical nanocrystals. Extrude by means of microfluidic spinnerets, acidifying to set off beta-sheet formation, embedding graphene in a tricky, elastic matrix.

- Covalent Cross-Linking with Boron or Nitrogen Dopants: Introduce boron atoms throughout detonation to create sp³ bridges between platelets, forming diamond-like nodes in a graphene community. This might increase shear energy to 10-20 GPa with out sacrificing tensile properties, verified by molecular dynamics.

- Electrospinning with Magnetic Alignment: Combine reactive graphene in a polymer dope, electrospin below magnetic fields to orient platelets, then pyrolyze the polymer, leaving aligned, sintered graphene fibers. Enhancements: Add ultrasonic waves for dynamic packing, focusing on <1 defect per 100 nm².

- Hierarchical Bundling by way of 3D Printing: Nanoscale print graphene inks layer-by-layer, utilizing click on chemistry (e.g., thiol-ene) for immediate cross-links. Scale as much as micro-bundles, then macro-cables, tapering density like a tree trunk to root.

- Dynamic Compression and Sintering: Apply gigapascal pressures in a diamond anvil cell, mixed with warmth, to induce partial sp²-to-sp³ transitions at overlaps, creating hybrid constructions akin to lonsdaleite—ultra-hard but versatile.

- Biomineralization Analogs: Introduce calcium or silica ions to reactive teams, mineralizing interfaces like nacre, including compressive energy and crack deflection.

- AI-Optimized Hybrid Composites: Simulate (by way of quantum computing) blends of fractal graphene with silk-mimetic polymers or boron nitride, optimizing ratios for 90% tensile effectivity. Fabricate by way of wet-spinning, testing at centimeter scales.

These aren’t exhaustive; hybrids abound—e.g., combining bio-templating with laser fusion. Every goal’s intention: shifting past low-load enhancements and polymer-like bonds to harness graphene’s full lattice energy.

Weaving and Laminating: Sensible Steps Ahead

Drawing from these, a viable course of would possibly begin with a high-solids dispersion of reactive fractal graphene, extruded by way of wet-spinning into aligned fibers, the place optimized cross-linkers (not mere condensations) guarantee graphene-dominant energy. Stack into nacre-like laminates, utilizing scorching isostatic urgent (5-20 GPa) to forge sp³ bonds, elevating shear (and thus total tensile) resilience to 10-20 GPa. Taper the construction: thick on the base for 7 GPa stresses, thinning upward.

Scaling leverages HydroGraph’s modular reactors, producing tonnage graphene for kilometer segments.

Be part of by way of overlap lamination, braid for redundancy, deploy from orbit. Prototypes should show cohesive failure, >90% load switch, by way of nanoindentation.

A Bridge to the Cosmos

Sorensen’s detonation-born graphene, fractal and reactive, ignites risk. But, as spider silk teaches, true mastery lies in hierarchy and adaptation.

Success means a tether with inter-platelet bond energy nearing single-crystal graphene (>100 GPa), verified by nanoindentation or pull-out exams, with >90% tensile switch effectivity. Centimetre-scale prototypes ought to present minimal defects (<1 per 100 nm² by way of TEM), failing cohesively, not delaminating, like a spider’s net holding below a gale. The total tether, massing below 500 tonnes, might be deployed from orbit, a lifeline to the cosmos. This graphene tether embodies our ‘sea-longing,’ a bridge to the celebrities woven from carbon’s hexagons, impressed by nature’s spinners and builders.

By innovating from first ideas—fusing, assembling, templating—we edge nearer to sewing the celebrities. This isn’t mere supplies science; it’s the warp and weft of humanity’s interstellar tapestry, an internet to catch the desires of Centauri and past.